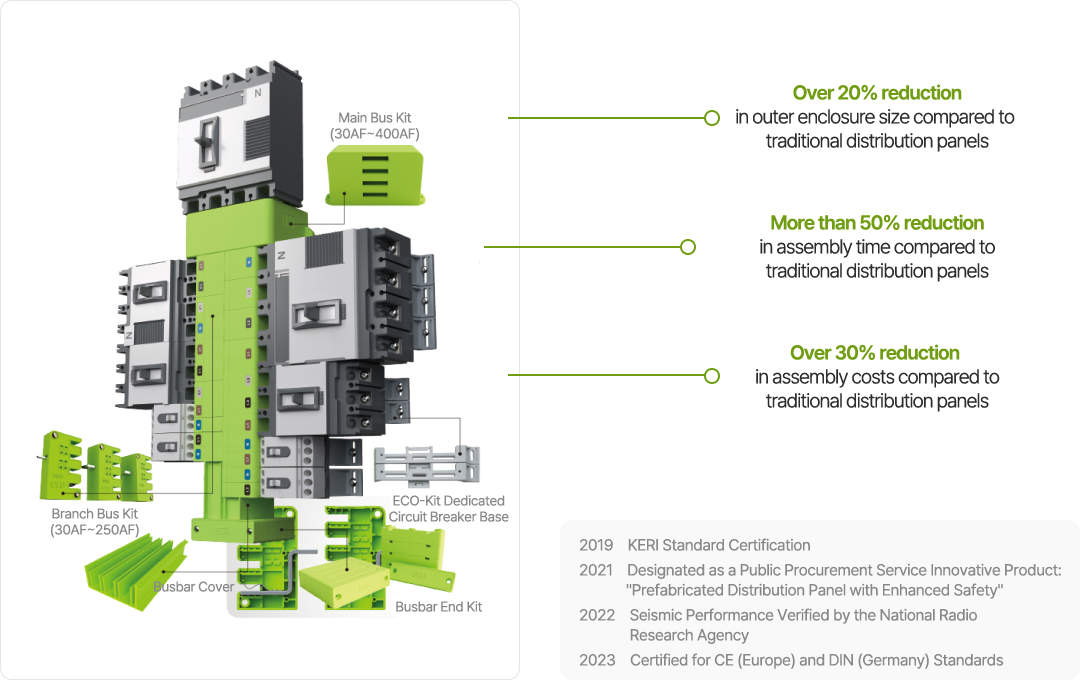

LINKBRIDGEPrefabricated Distribution Panel with Enhanced Safety

LINKBRIDGEPrefabricated Distribution Panel with Enhanced Safety

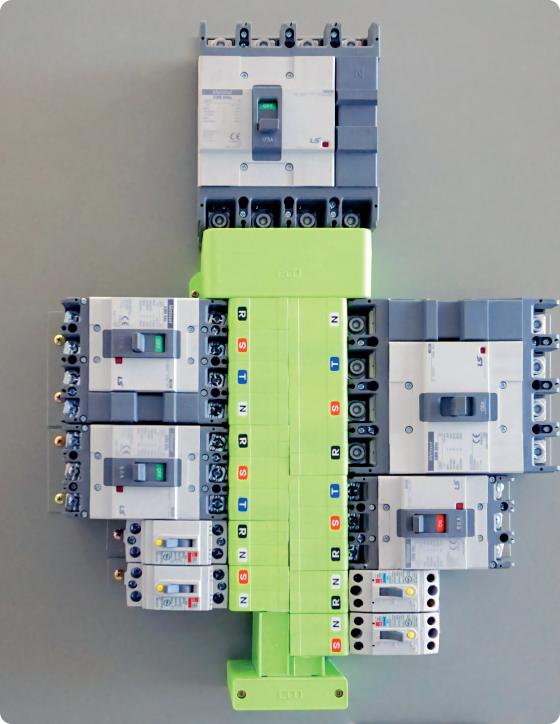

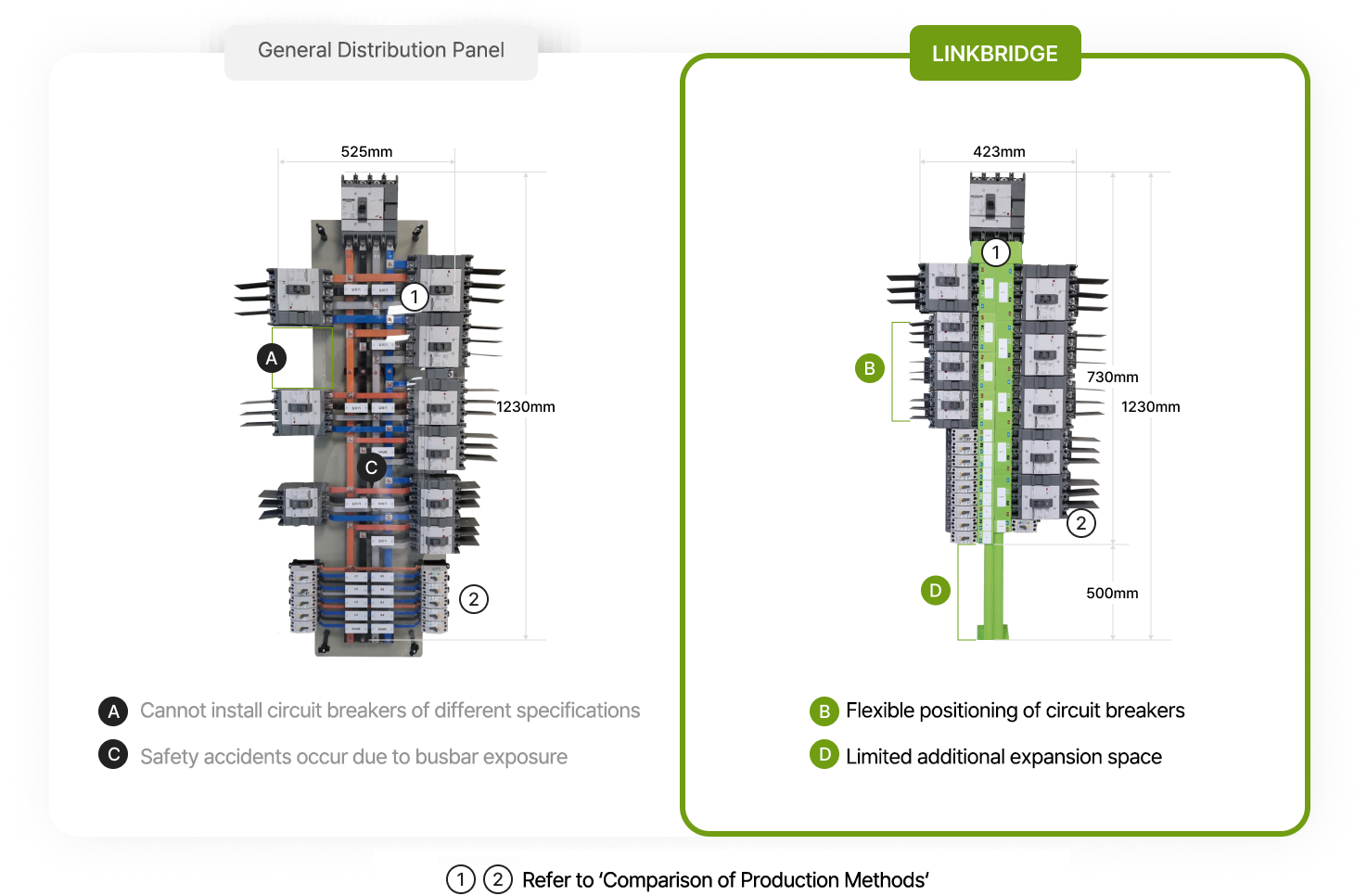

Safety Accident Prevention

Prevention of electric shock and short circuits

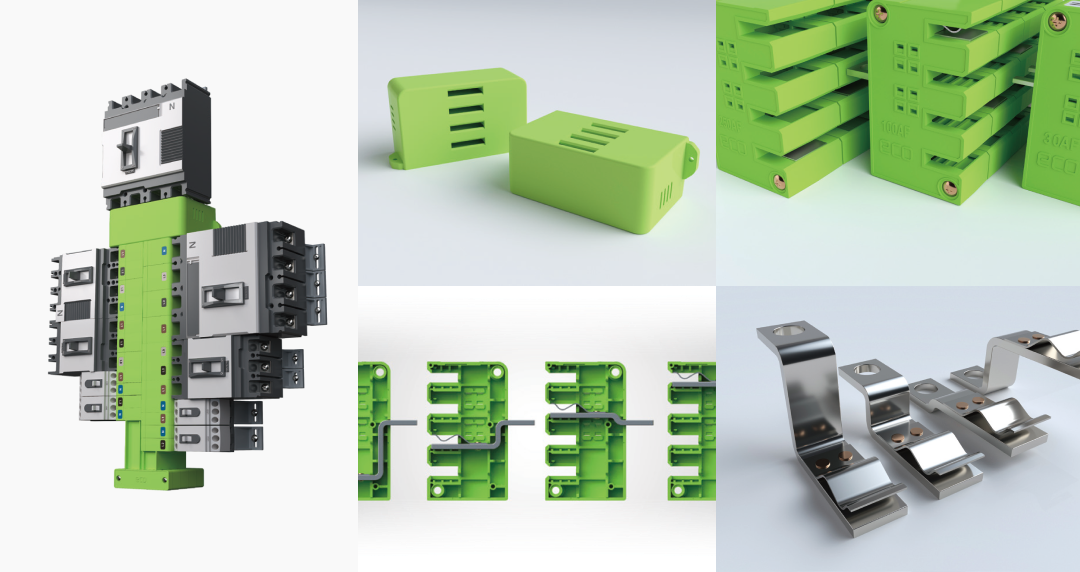

Fire Spread Prevention

Application of flame-retardant materials

Seismic Resistance

Verified through seismic testing

Busbars within the distribution panel are placed inside insulated cases to prevent electric shock and short-circuit accidents caused by busbar exposure

The insulated case is made of flame-retardant ABS material to minimize damage in the event of a fire

Provides safety against vibration and earthquakes equivalent to a Richter scale of approximately 7.8