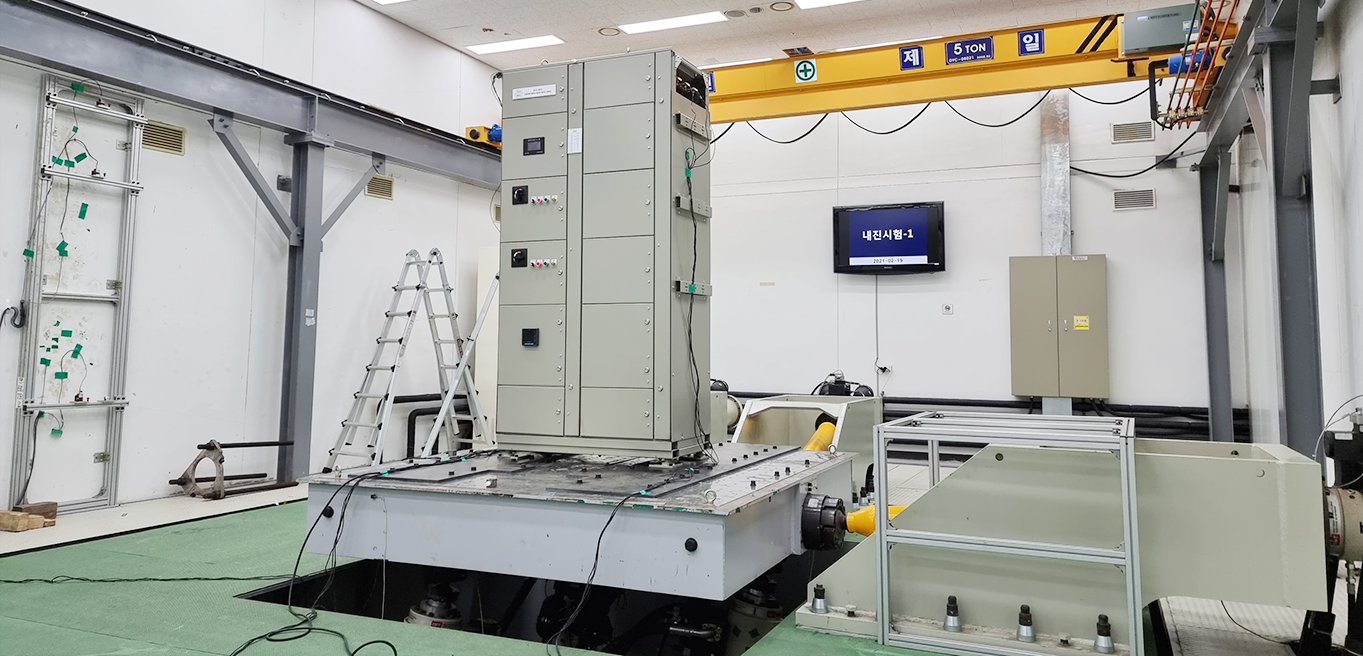

technology test

Eco Powertec products have been recognized for their reliable quality and technological innovation through testing and certification conducted by authorized institutions.

Products that are designated as outstanding in performance, technology, or quality to improve the quality of procured goods and support the sales of small and medium-sized enterprises.

International Standard (USA)_KTL Test Report 22-000237-01-1~4

Domestic Standard_KTL Test Report 21-004521-01-1~4

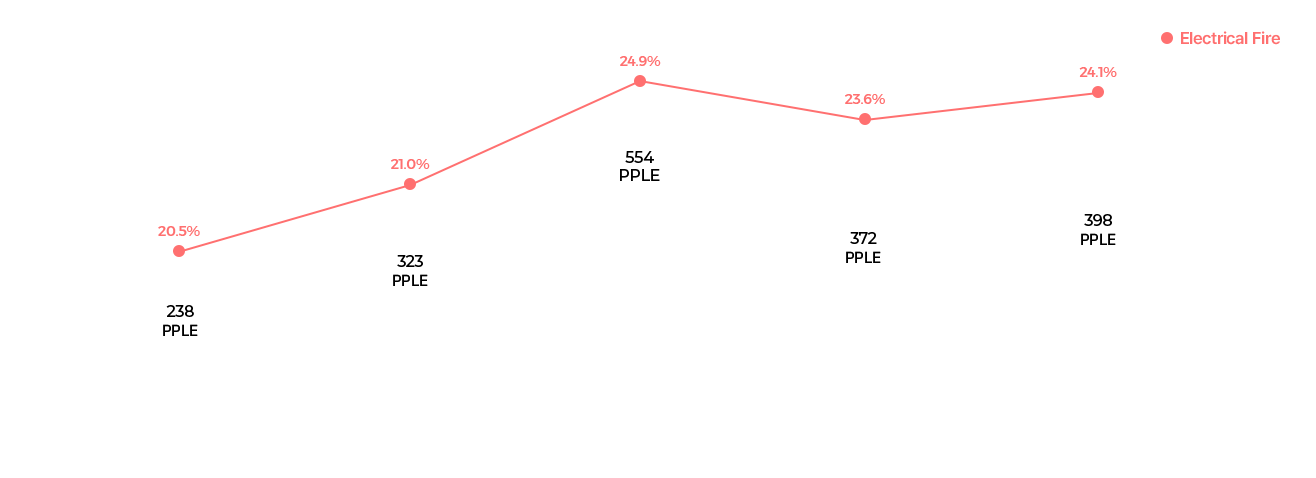

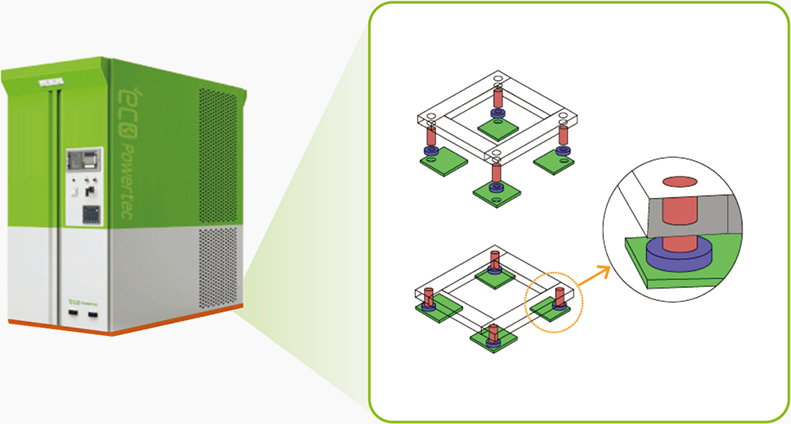

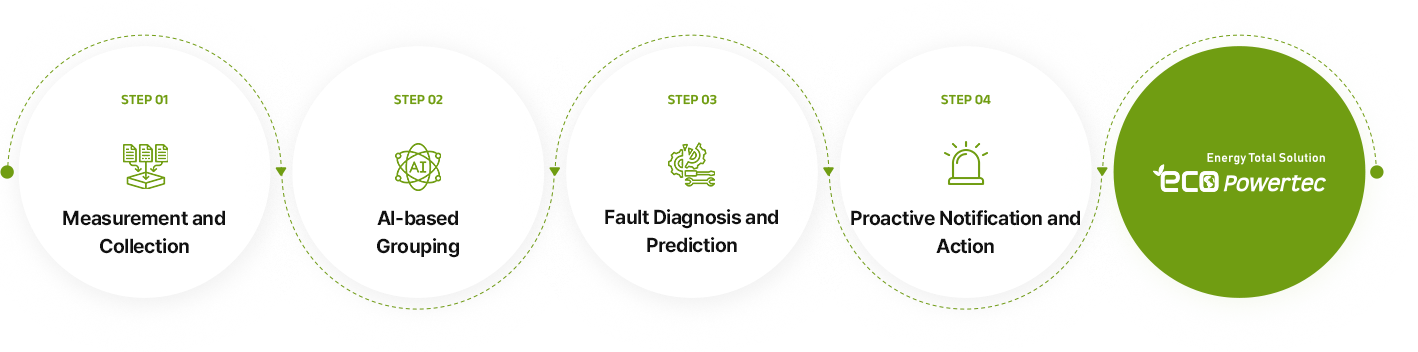

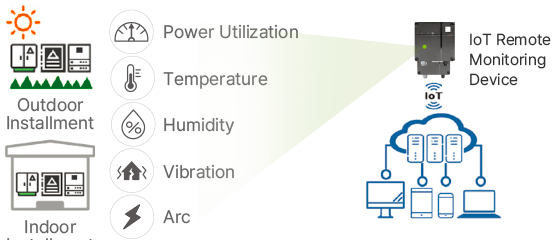

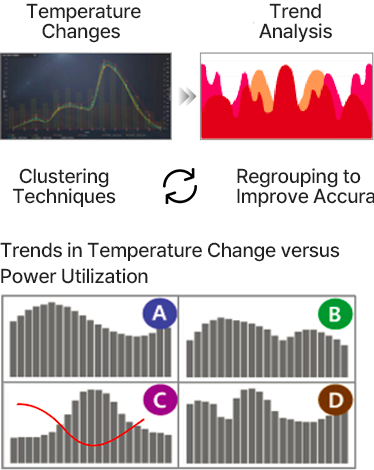

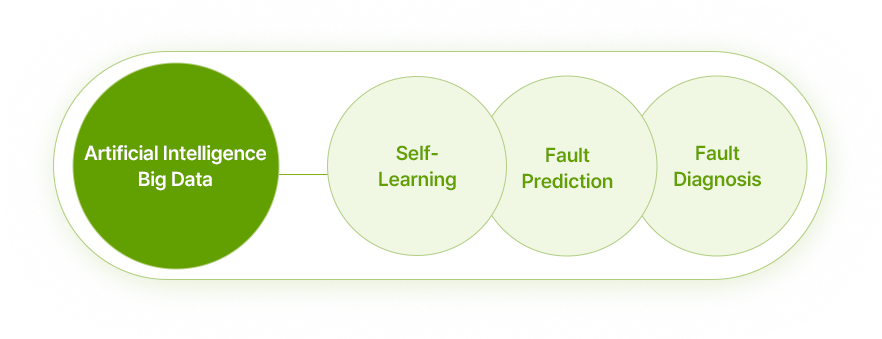

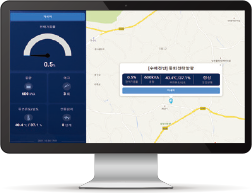

Collection of various environmental and status information and application of AI-based grouping technology derived from trend analysis to predict failures and diagnose failures in real time

Collect data from switch boards installed in various locations in various regions to create big data

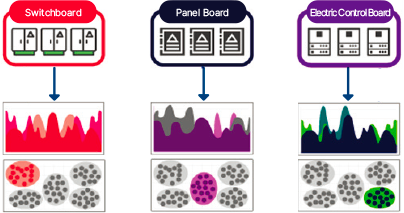

Categorize the collected data into groups with similar capacities to the environment where the switchboard is installed

Among the classified data, busbar and transformer temperatures with similar trends in power utilization are grouped together

Example) When electricity flows, the temperature of components, wires, and busbars increases

Check whether it is a temporary change in usage pattern or external environmental change, whether there is a failure for the cause. If there is no failure factor, regroup(Re-group the switchboards with similar patterns)

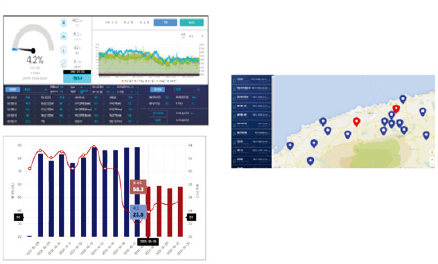

When it is determined that the cause is the equipment itself without other external factors, manager is notified, and precision diagnosis is initiated

By collecting various environmental and status information and applying AI-based grouping technology based on trend analysis, it is possible to predict and respond to faults in advance with the help of switchboards that can predict and diagnose faults in real time

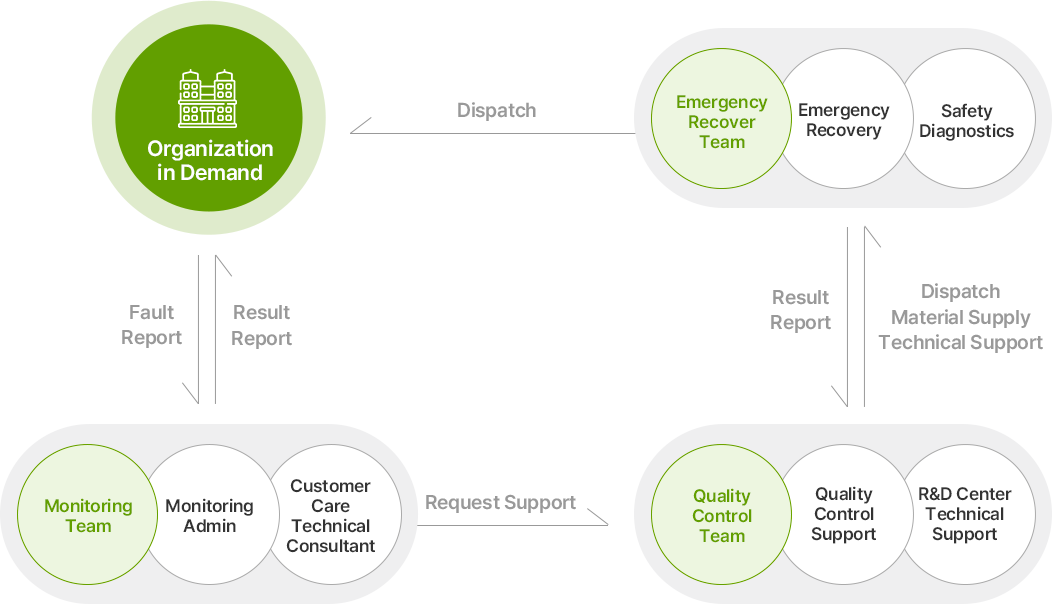

Eco Powertec operates TOC (Total Operating Center) and establishes a 24-hour real-time monitoring and emergency response system